WASTE IS MORE EXHIBITION

"Trash" is a word with which everyone is acquainted. But no one is pleased with the persistence of these wastes, even though we are the ones who create them to enrich our lives. "Disposal" by dumping, burying, or burning is not the sole final effort we can take together

to promote the sustainability of our planet, however.

We challenge you to transform your view on "waste" as a substitute material that is "not worthless" anymore, with eight overlooked waste materials from industrial and domestic sources. Bottle caps and UHT boxes from households, sugarcane from agriculture, coffee chaff, eggshells, fabric dust, wood dust and PVC edge banding from industrial waste are all recycled to achieve potential through innovation. Unite with eight designers with diverse interests and aptitudes to develop waste materials into unique, accessible items for everyone.

A consumption choice that considers the quality of life of humans and the environment while reinforcing the idea "there is no waste, only valuable resources."

An exhibition displays possibilities by MORE, a collaboration between the research team from PTT Innovation Institute and HG Next Co., Ltd.,

a designer, manufacturer, and furniture distributor committed to research, development, and design to be a complete solution for transforming waste into renewable resources.

"Trash" is a word with which everyone is acquainted. But no one is pleased with the persistence of these wastes, even though we are the ones who create them to enrich our lives. "Disposal" by dumping, burying, or burning is not the sole final effort we can take together

to promote the sustainability of our planet, however.

We challenge you to transform your view on "waste" as a substitute material that is "not worthless" anymore, with eight overlooked waste materials from industrial and domestic sources. Bottle caps and UHT boxes from households, sugarcane from agriculture, coffee chaff, eggshells, fabric dust, wood dust and PVC edge banding from industrial waste are all recycled to achieve potential through innovation. Unite with eight designers with diverse interests and aptitudes to develop waste materials into unique, accessible items for everyone.

A consumption choice that considers the quality of life of humans and the environment while reinforcing the idea "there is no waste, only valuable resources."

An exhibition displays possibilities by MORE, a collaboration between the research team from PTT Innovation Institute and HG Next Co., Ltd.,

a designer, manufacturer, and furniture distributor committed to research, development, and design to be a complete solution for transforming waste into renewable resources.

Project and Exhibition by MORE

Art direction by studio 150

Graphic design by Romrawin Pipatnadda

Exhibition consultant by THINKK STUDIO

Curated by by Apisara Hophaisarn

Art direction by studio 150

Graphic design by Romrawin Pipatnadda

Exhibition consultant by THINKK STUDIO

Curated by by Apisara Hophaisarn

Eggs are an invaluable ingredient in the kitchen. However, when cooking is complete, we are left with 650 million kilograms of "eggshells" per year. Even though "eggshells" readily decompose naturally, they can create solid waste problems affecting our quality of life and the environment. However, when combined with material innovation, "eggshells" can produce a strong and durable product from its 95% calcium carbonate- a compound found in limestone, seashells, and cement. An exciting alternative to waste management from daily life to a final product is unique, displaying different internal and external "eggshells" colours.

Designer : Spirulina Society

Designer : Spirulina Society

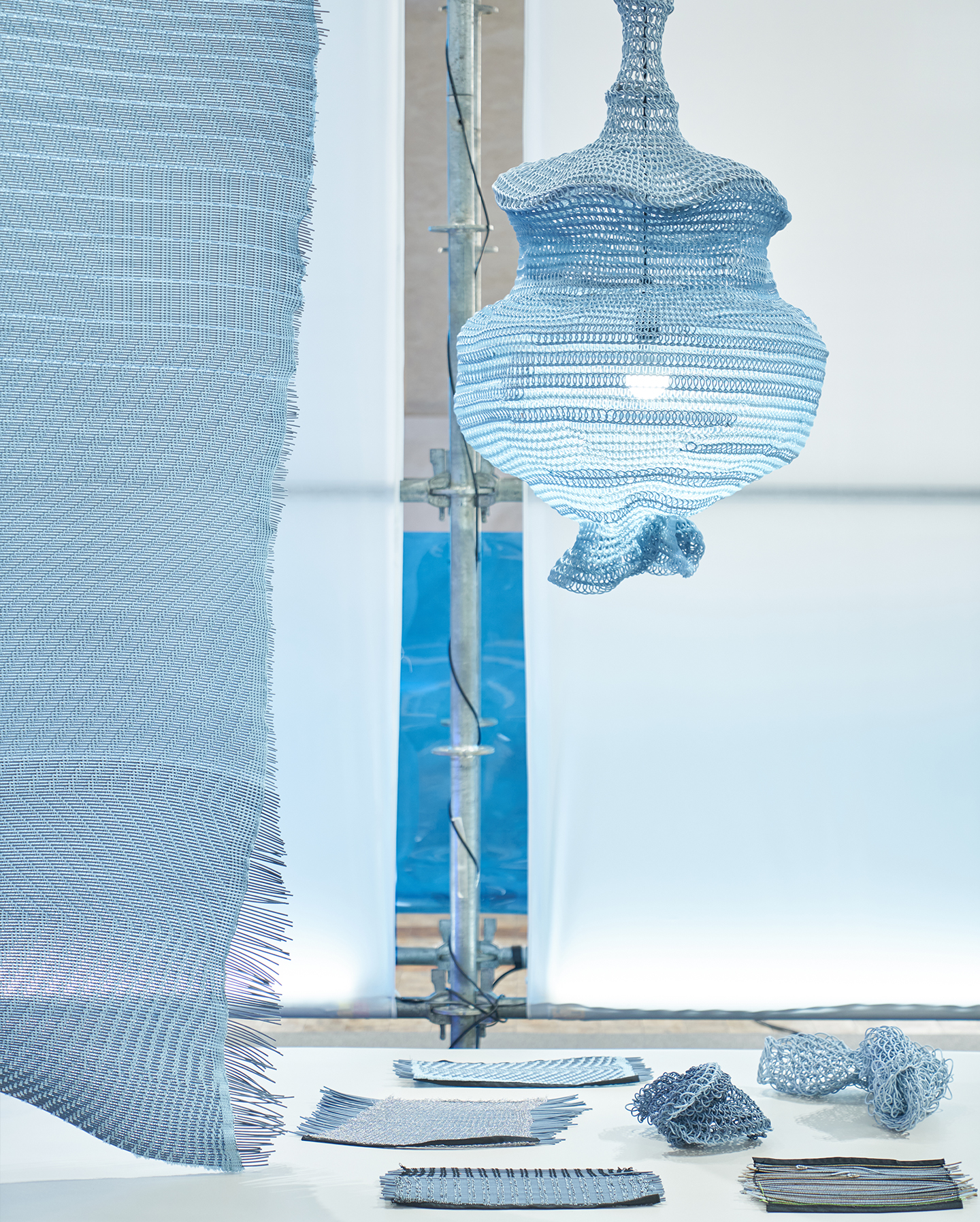

“Fabric dust" dramatically impacts our environment by making fibres, yarns, and fabrics, including sewing, throughout 4,829 factories across the country. Our innovation reveals the potential and benefits of "fabric dust", which is usually used as fuel or scrapped in landfills into solid and durable renewable material. "Fabric dust" could be formed in sheet or rattan fibre that retains the original materials' attractive pattern and proposes a unique and beautiful fabric-like appearance.

Designer : TAKORN TEXTILE STUDIO

Designer : TAKORN TEXTILE STUDIO

About 4.4 billion plastic bottles are produced in Thailand annually. Still, only 21% of plastic is recyclable due to waste sorting, colour separation and contamination limitations. HDPE and PP plastic “bottle caps” are frequently discarded due to those limitations- despite being durable, flexible, and lightweight. We view this as an opportunity and preen this leftover into alternative materials as durable and colourful materials that uniquely display their source.

Designer : NUTRE JEWELLER

Designer : NUTRE JEWELLER

While we enjoy the taste of coffee daily, up to 20 tons of waste from the coffee roasting process or "coffee chaff", is created yearly. We shift from the cost of waste disposal to reducing the impact on the ecosystem to invest in innovative materials instead. As an alternative material, "coffee chaff" is intended to replace virgin plastic sheets but preserve the same properties. Ready to further develop into products that create maximum benefits and reduce environmental impact while simultaneously creating unique business opportunities.

Waste owner : Café Amazon, a chain of Thai coffeehouses primarily found inside malls, city centres and petrol stations with more than 4,120 stores worldwide.

Designer : KITTAKHON

Waste owner : Café Amazon, a chain of Thai coffeehouses primarily found inside malls, city centres and petrol stations with more than 4,120 stores worldwide.

Designer : KITTAKHON

"Aluminium foil from UHT boxes" that we are familiar with in our daily lives has been discarded at least 75,000 tons yearly. These boxes are made of 6 layers of paper, polyethene plastic, and aluminium foil to strengthen the container, making it problematic to process these multi-layered materials further. With innovation from Advanced Mat, we can layer the "Aluminium foil from UHT boxes" and transform them into recyclable materials for a beautiful, polished, lightweight, yet durable variety of refinement.

Designer : mitr.

Designer : mitr.

Wooden furniture is a critical element of necessity, especially rubber wood, the primary material for more than 60% of the total output. In contrast, furniture production generates almost 1 ton of "wood dust" per month, which ends up as fuel or re-forming into incense for religious use. We combine the "wood dust" innovation into a renewable material that offers colour from the source but still has properties. "Wood dust" can be brought back into polishing, cutting, and drilling like natural wood endlessly as resources by adding value and further growing business opportunities.

Waste owner : HOOG, a global standard furniture brand, specialises in woodworking and merging the circular economy through design into daily lives

Designer : o.d.a

Waste owner : HOOG, a global standard furniture brand, specialises in woodworking and merging the circular economy through design into daily lives

Designer : o.d.a

PVC or polyvinyl chloride can be developed in various forms, including "PVC edge banding" for wood furniture production. Nevertheless, more than 400 kilograms of "PVC edge banding" scraps per year are produced from particle board furniture factories before shipping the complete furnishings to us. We unite discarded "PVC edge banding" scraps with material innovation to create an alternative material that provides heat, moisture, and scratch resistance properties. The "PVC edge banding" offers a consumption alternative with a unique identity and colours similar to different types of wood to extend existing resources back into furniture production again.

Waste owner : HARV, a renewable furniture brand that fosters the consumer's quality of life and the environment's health dearest to us.

Designer : DESIGNERD

Waste owner : HARV, a renewable furniture brand that fosters the consumer's quality of life and the environment's health dearest to us.

Designer : DESIGNERD

Agriculture creates enormous leftovers from harvesting, particularly "sugarcane tops", causing the significant plantations in the northeast region to struggle with the burning process during the harvest. "Sugarcane tops" is considered one of the primary causes of air pollution or PM 2.5 that affect the health and life of Thai people. We redirect from burning waste to witnessing the benefits of "sugarcane tops" through material innovation. Encourage how we can address other forms of agricultural waste in the near future to drive the economy linked to the agricultural sector while reducing the negative impact on our life quality.

Designer : MORE team and Chanya Suoavong